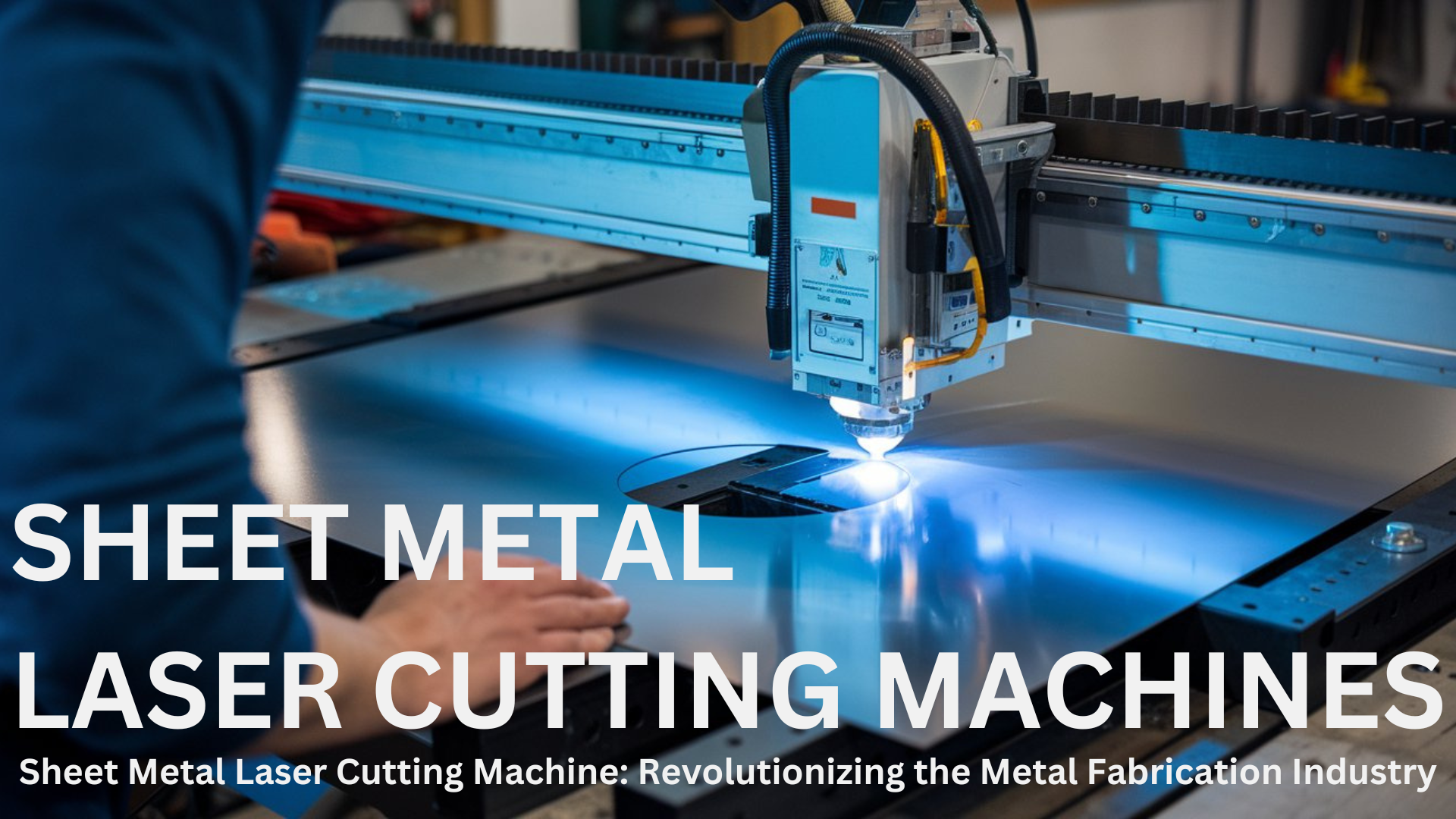

The heavy metal manufacturing industry is essential to a wide array of sectors, including construction, automotive, aerospace, and defense. Among the many technologies that have revolutionized metalworking, laser cutting machines have risen to prominence for their precision, speed, and ability to handle even the most challenging materials. Specifically, metal laser cutting machines for heavy metal applications are a critical investment for manufacturers seeking efficiency, flexibility, and reduced operational costs.

As manufacturers look to optimize production processes, choosing the right laser cutting machine tailored to their needs becomes pivotal. The heavy metal industry often deals with thick materials, requiring machines that can maintain high performance without sacrificing precision. For businesses looking to make informed investments, FABTECH USA and EuroBLECH Germany, two of the largest metalworking expos in the world, offer unparalleled opportunities to explore cutting-edge technologies, compare manufacturers, and ultimately choose the best solutions for their operations.

In this blog, we will explore the advantages of metal laser cutting for heavy applications, how FABTECH USA and EuroBLECH Germany can guide businesses to the right laser cutting solution, and how to secure free tickets for these major events in 2024.

Why Metal Laser Cutting Machines Are Ideal for Heavy Metal Manufacturing

Laser cutting technology uses a high-powered laser beam to cut, melt, or vaporize metals with extreme precision. For the heavy metal manufacturing industry, laser cutting machines offer significant benefits that make them indispensable:

1. High Precision and Accuracy: Metal laser cutter excel in achieving precise cuts even with materials as thick as steel and other hard metals. They can create intricate designs with minimal waste, resulting in optimal material usage.

2. Speed and Efficiency: Laser cutting processes are faster than traditional cutting methods, such as plasma cutting or mechanical sawing, reducing overall production times. This speed is critical when working with heavy metals in high-demand industries.

3. Versatility Across Materials: Whether it’s carbon steel, stainless steel, aluminum, or titanium, laser cutting machines can handle a wide range of metals with ease. For the heavy metal sector, this versatility is invaluable.

4. Lower Operational Costs: By reducing material waste, labor, and energy consumption, laser cutting machines can lower operational costs for manufacturers over the long term.

5. Automation and Integration: Modern laser cutting machines are increasingly automated, which allows them to be integrated into smart manufacturing environments, boosting productivity with minimal human intervention.

The Role of FABTECH USA and EuroBLECH Germany in Helping Choose the Right Machine

While the benefits of laser cutting machines are clear, choosing the right machine tailored to your specific manufacturing needs is not always straightforward. This is where major industry events like FABTECH USA and EuroBLECH Germany can be invaluable.

1. FABTECH USA: North America’s Premier Metalworking Expo

Taking place in 2024, FABTECH USA is the largest metal forming, fabricating, welding, and finishing event in North America. It attracts thousands of exhibitors and visitors from around the world, showcasing the latest technologies and innovations in metalworking, including laser cutting machines.

Live Demonstrations and Exhibits: FABTECH gives you the chance to see live demonstrations of laser cutting machines, including those built for heavy metal applications. Witnessing these machines in action will help you evaluate their performance, cutting speed, and efficiency in real-world scenarios.

Comparing Solutions: With hundreds of manufacturers displaying their equipment, you can compare various machines and features. Leading laser cutting brands will be present, offering a comprehensive overview of what’s available in the market.

Expert Insights: FABTECH offers seminars and workshops led by industry experts. These sessions will cover topics such as laser technology advancements, best practices for cutting heavy metals, and how to integrate these machines into your production lines.

2. EuroBLECH Germany: The Leading Sheet Metal Working Technology Exhibition

Scheduled for 2024, EuroBLECH Germany is the world’s largest trade fair dedicated to sheet metal processing, making it a global hub for laser cutting technology. The event is ideal for manufacturers looking for cutting-edge solutions for heavy-duty applications.

Technology at the Forefront: EuroBLECH showcases the latest innovations in laser cutting, with a focus on automation, sustainability, and Industry 4.0 integration. Manufacturers can explore how these advancements translate into more efficient, cost-effective operations for their heavy metal processes.

Networking Opportunities: The event provides an excellent platform to connect with machine manufacturers, service providers, and other industry professionals. You’ll have the opportunity to ask questions, get recommendations, and build relationships that can assist in your buying decision.

Tailored Solutions: Many manufacturers use EuroBLECH to launch new products or demonstrate customized laser cutting machines designed for specific industry needs, including heavy metal fabrication. This allows you to find machines specifically tailored to your operational requirements.

Securing Free Tickets for FABTECH USA and EuroBLECH Germany 2024

Attending FABTECH USA and EuroBLECH Germany can be a game-changer for your business, and there are several ways to obtain free tickets:

1. Early Registration: Both expos typically offer free or discounted tickets for attendees who register early. Keeping an eye on their official websites and signing up for newsletters can give you a head start in securing free entry.

2. Exhibitor Invitations: Many exhibitors offer free passes to potential clients. If you are already in contact with machine manufacturers or suppliers, ask if they are exhibiting and whether they can provide you with a free pass to the event.

3. Industry Associations: Professional associations and industry organizations often have partnerships with the expos and may offer free tickets to members. Consider joining relevant associations to take advantage of these perks.

4. Contests and Promotions: FABTECH and EuroBLECH sometimes run contests or promotional campaigns that offer free tickets. Follow their social media accounts and stay updated on announcements for a chance to win.

Conclusion

Investing in the right laser cutting machine for heavy metal applications is crucial to staying competitive in the manufacturing industry. FABTECH USA and EuroBLECH Germany 2024 are prime opportunities to explore the latest technologies, meet with industry experts, and make informed decisions about your next laser cutting machine purchase. By attending these expos, you can gain valuable insights and possibly secure free tickets through early registration or exhibitor invitations, ensuring that you stay ahead of the curve in the rapidly evolving world of metalworking.