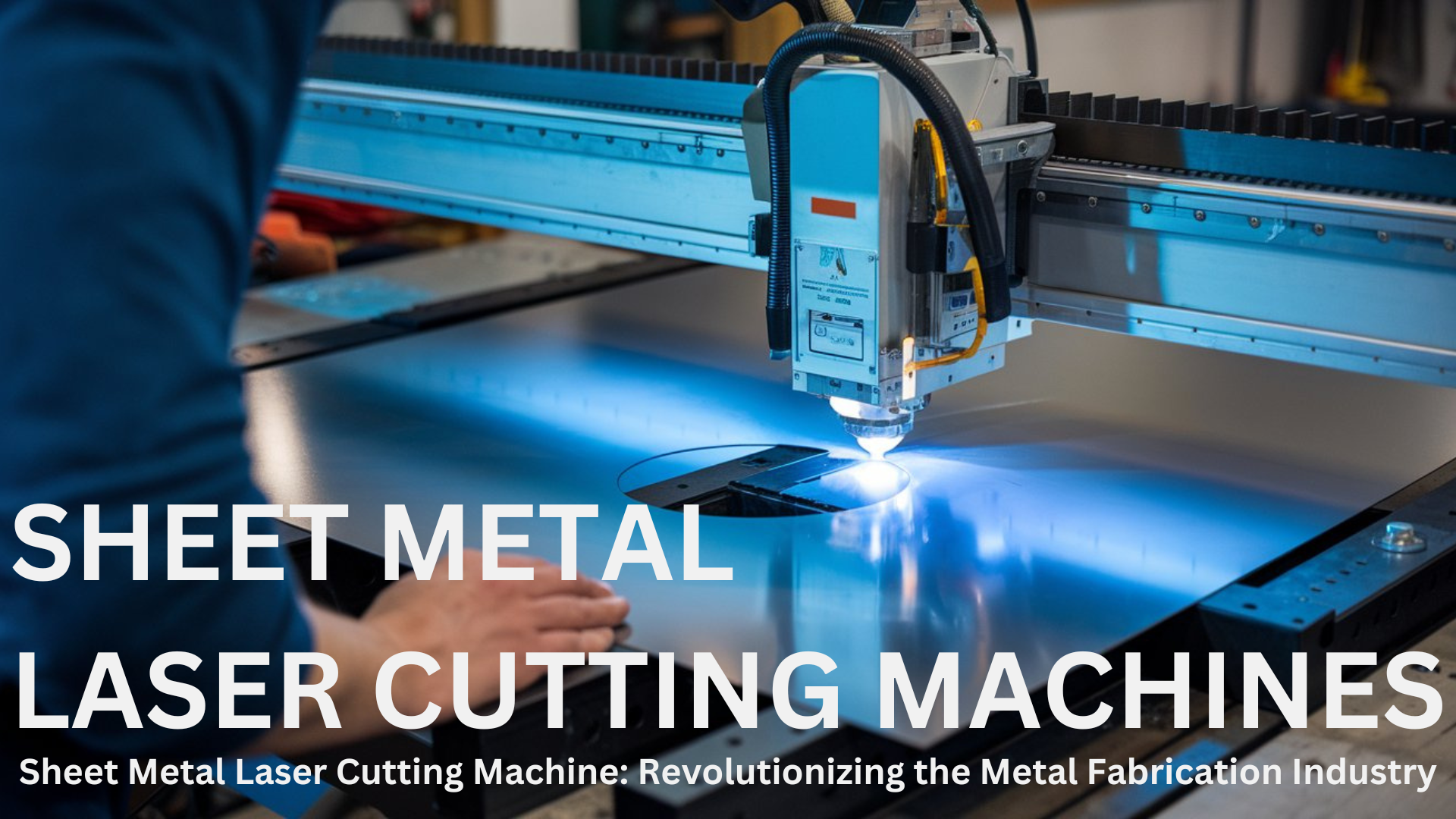

Introduction: Laser Cutting Machines Explained

A sheet metal laser cutting machine is a cutting-edge tool that uses laser beams to slice through various metals with high accuracy and speed. Unlike traditional cutting methods, which can be slow and imprecise, laser cutting is fast, efficient, and capable of handling complex designs with ease. It’s a must-have for any metal fabrication business looking to stay ahead in the market.

Why Sheet Metal Laser Cutting Machines Are Better

- Superior Accuracy: Laser cutting provides clean, precise cuts, making it ideal for intricate designs that other methods can’t handle.

- Faster Production: With laser technology, cutting times are significantly reduced, boosting productivity and enabling quicker turnaround times.

- Versatile Applications: From thin sheets of aluminum to thicker steel and iron, laser cutting machines can handle various materials without the need for multiple tools or setups.

- Cost Savings: Reduced waste, lower maintenance costs, and faster production all contribute to significant cost savings over time.

Current Trends in Laser Cutting Technology

Companies are increasingly adopting laser cutting machines as part of their shift towards automated and smarter manufacturing. With trends like 3D laser cutting and the integration of AI for even greater precision, businesses can produce more complex and high-quality products. This technological leap is allowing companies to reduce costs, enhance quality, and stay competitive.

Conclusion: Don’t Let Your Competitors Get Ahead

If you’re still relying on outdated cutting methods, it’s time to rethink your strategy. A sheet metal laser cutting machine offers everything you need to take your fabrication business to the next level: speed, precision, and versatility. Don’t get left behind—invest in the future of cutting technology today.

Confused about which laser machine to choose? Contact us at +919925036495 or visit the best laser cutting machine manufacturer for guidance.