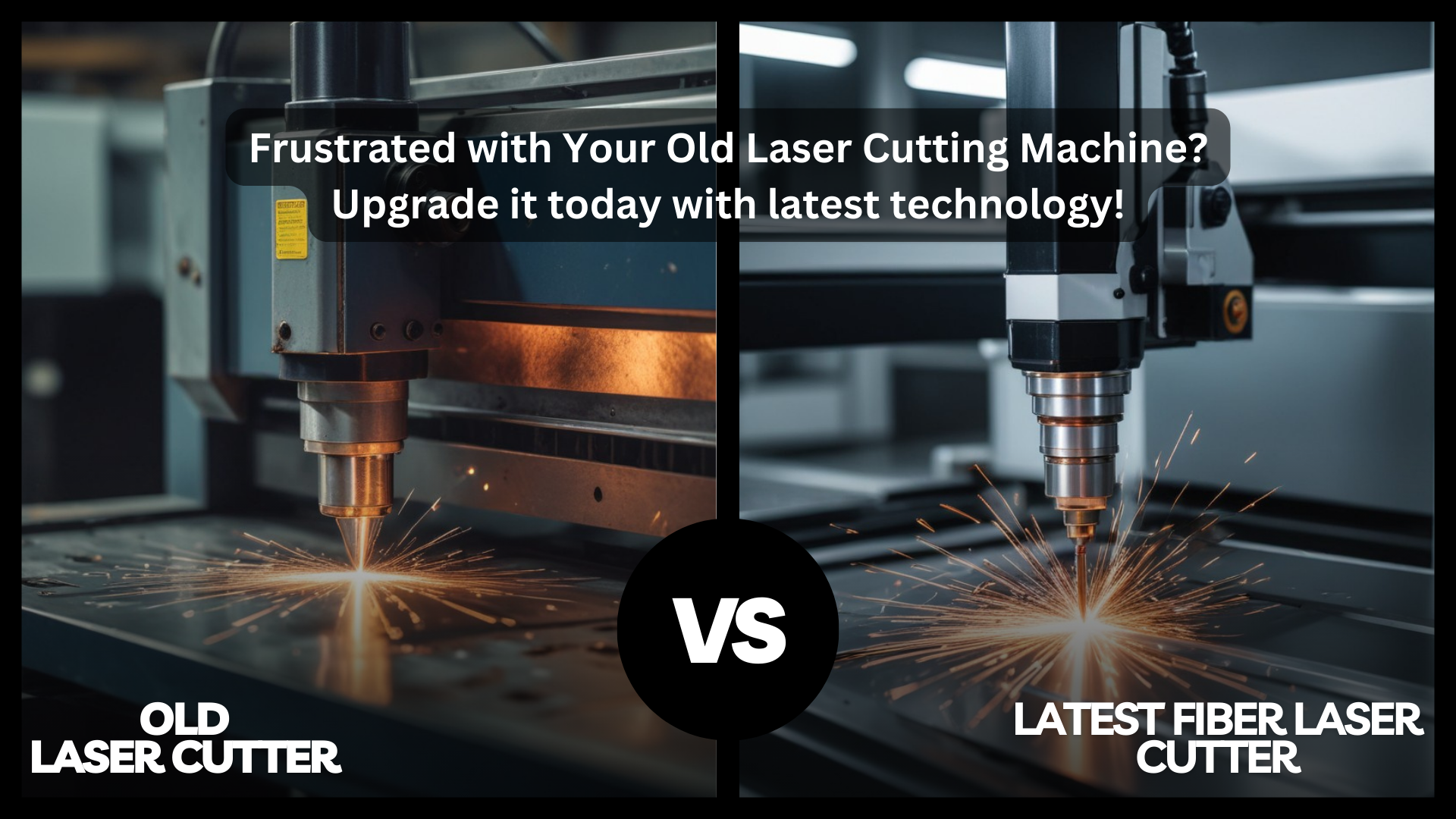

Are you tired of your trusty old laser cutting machine which is not quite keeping up with the demands of the modern fabrication? It’s no secret that these machines, once the cutting-edge (pun intended) marvels of technology, become a real headache as they age. What was once a pinnacle of efficiency and precision gradually degrade into a sluggish, inaccurate behemoth that costs you time and money.

Why You Should Upgrade Your laser cutting Machine

In today’s fast-paced world of manufacturing, staying ahead of the curve is crucial. It is like trying to keep up in a Formula 1 race with a Model T Ford: it’s just not going to happen. Similarly, sticking with outdated machinery in a competitive market is a recipe for disaster and you will also be losing money. Now a days upgrading your laser cutting machine isn’t just a luxury; it’s a necessity if you want to remain competitive and meet the increasing demands of your customers.

The Importance of Upgrading to Fiber Laser Cutting Technology

Following are the reasons for which you should upgrade your machine now:

- Loss of Efficiency and Accuracy: As traditional laser cutters age, they tend to lose their edge literally. Wear and tear of the laser head and the machine can lead to decreased efficiency and accuracy, which results in wasted materials and costly rework.

- Time Savings: In the world of metal fabrication, time is money. Fiber laser cutting technology based machines are significantly faster as compared to older CO2 machines. This means you can produce more parts in less time, increasing your overall productivity and profitability.

- Automation and AI Integration: The latest fiber laser cutting machines come equipped with advanced automation features and even AI integration. This means fewer manual interventions, reduced operator error, and smoother workflow processes. Plus, AI algorithms can optimize cutting paths for maximum efficiency, further enhancing productivity of the machine.

- Customization and Flexibility: Modern fiber laser cutters offer greater flexibility and customization options, allowing you to cater to a wider range of client needs. Whether it’s intricate designs or complex geometries, these machines can handle it with ease, giving you a competitive edge in the market.

- Cost Savings in the Long Run: While the upfront cost of upgrading may seem daunting, it’s essential to consider the long-term savings. Improved efficiency, reduced downtime, and lower maintenance costs can quickly offset the initial investment, leading to significant cost savings over time.

Conclusion

In conclusion, holding onto outdated laser cutting machines is a surefire way to fall behind the competition and hemorrhage money in the process. By embracing the latest fiber laser cutting technology, you not only ensure greater efficiency and accuracy but also position yourself as a leader in the industry. So don’t let your old machines hold you back: take the leap and upgrade to stay ahead of the curve. Your bottom line will thank you.