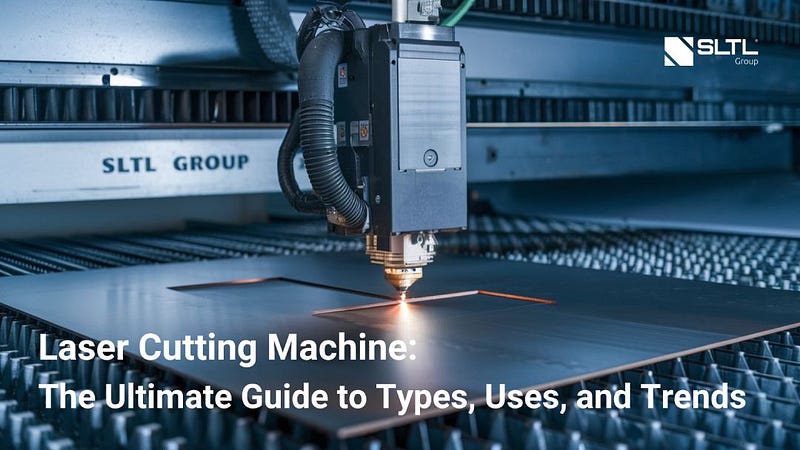

In today’s rapidly evolving manufacturing landscape, Laser Cutting Machine have emerged as indispensable tools for precision cutting across various industries. This guide explores the technology, types, applications, industries, benefits, and emerging trends associated with these advanced machines.

Overview of Laser Cutting Technology

Laser cutting technology utilizes a high-powered laser beam to cut, engrave, or etch materials with exceptional precision. This method has gained immense popularity due to its versatility, speed, and accuracy compared to traditional cutting methods. Industries ranging from automotive to aerospace and beyond are increasingly adopting laser cutting for its efficiency and cost-effectiveness.

Different Types of Laser Cutting Machines

There are primarily two types of cnc laser cutting machine widely used today:

1. CO2 Laser Cutting Machine:

Specific Uses: Ideal for cutting thin metals, non-metallic materials, and laser marking applications due to its ability to produce high-quality cuts and intricate designs.

2. Fiber Laser Cutting Machine:

Specific Uses: Known for cutting thick metals with speed and precision, including stainless steel, aluminum, and other alloys. It excels in industrial applications requiring high throughput and efficiency, such as sheet metal fabrication and automotive components.

Industries with Highest Demand for Laser Cutting Machines

The demand for laser cutting machines is particularly high in several key industries:

- Automotive Industry: Used for precise cutting of automotive parts and components.

- Aerospace Industry: Essential for manufacturing intricate aerospace components with high strength and lightweight materials.

- Electronics Industry: Utilized in the production of electronic devices and circuit boards for precise cutting and etching.

Benefits of Using Laser Cutting Machines

Businesses and manufacturers prefer fiber laser cutting machine for several compelling reasons:

- Precision and Accuracy: Ensures intricate designs and tight tolerances.

- Versatility: Cuts a wide range of materials with minimal setup changes.

- Speed and Efficiency: Increases productivity and reduces production time.

- Cost-Effectiveness: Reduces material waste and operational costs compared to traditional cutting methods.

Emerging Trends in Laser Cutting Machine Usage

As technology advances, new trends in laser cutting machines are shaping the market:

- Integration with CNC Systems: Enhancing automation and precision through Computer Numerical Control (CNC) systems.

- Laser Cutting in Additive Manufacturing: Incorporating laser cutting into 3D printing and additive manufacturing processes for hybrid manufacturing solutions.

- Advancements in Fiber Laser Technology: Continued improvements in fiber lasers for higher power, faster speeds, and broader material compatibility.

The evolution of Laser Cutting Machines continues to revolutionize modern manufacturing across diverse industries. As technology progresses, these machines are poised to play an even more pivotal role in shaping the future of production and innovation.

This guide provides a comprehensive overview of laser cutting technology, types, applications, industries, benefits, and emerging trends, showcasing why these machines are at the forefront of modern manufacturing processes.

You can learn more about laser cutting machine at the world famous exhibition called FABTECH and EuroBLECH which is happening in USA and Germany respectively. Do visit their.